Dear friends,usually many people wonder what is faux leather,and whether faux leather is better than real leather?

today I am gonna share you some information regarding to faux leather.

first let me inform you the faux leather manufacturing process

synthetic leather includes: pu leather,pvc leather,microfiber leather and silicone leather

faux leather manufacturing process

PVC leather manufacturing process

how to manufacture pvc leather vinyl fabric?

normally there are 2 ways for manufacturing pvc leather

- the first way is calendering way.

so firstly we should mix the raw material PVC and pigment etc, and make the material in a good solid shape.

then we coated the mixed material on the fabric ,until this procedure the semi-finished material we call base material.

so the base material including 2 layers: pvc layer on the surface and backing is fabric.

then the base material will be sent into a foaming machine,which is a long production line with high temperature,the mixed material will foaming here,so the pvc will be thicker,the thickness of pvc layer can be double of the base pvc layer.

after foaming, the material will be embossed with texture,here we use embossing roller which has texture on the roller,you can think it as a mould,texture on the roller will be transfered to the surface of pvc layer,then we can got different texture.

then we will do surface treatment,like adjust the color or printing some drawings on the surface.

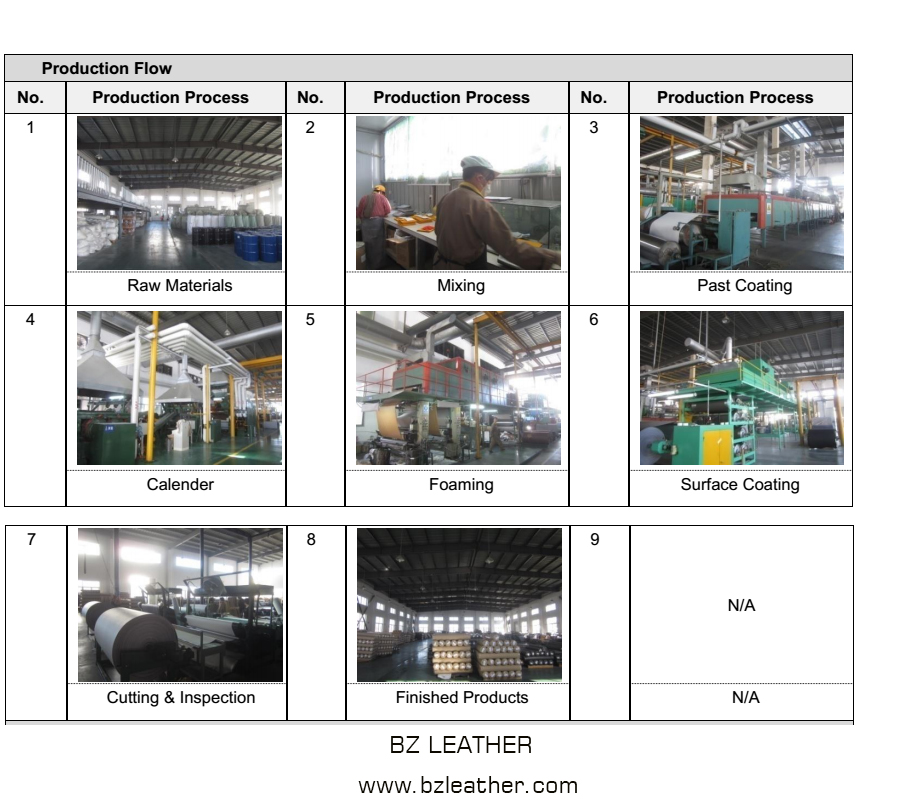

below is the production flow of the pvc leather

2:the second way is release paper way

the release paper is one kind of special paper which has texture on the paper,so it can transfer the texture from the release paper to the pvc layer when the paper is being released from the pvc layer.

first we mixed the material in a good fluid shape,then we coated the material on the release paper.

some times we need foaming,sometimes there is no foaming,after coating on the release paper we got the pvc layers,

then we will coating the glue on the pvc layers, and finally the pvc layers will be coated on fabric,the glue will stick the pvc layer with the backing fabric. and then we seperate the release paper with the pvc layer,and we got the finished pvc leather.

PU leather manufacturing process

how to manufacture pu leather?

there is also 2 ways of pu leather manufacturing

1:first way is wet pu leather manufacturing method

pu leather material production flow is different from that of pvc leather,

pu leather has no foaming process ,no calendering process,

firstly,we the backing fabric will go through the water to make it wet.

secondly,we will used the mixed polyurethane material to coat on the wet fabric.

thirdly,the pu coated on fabric material will go through a sink,which includes DMF material

(N,N-Dimethylformamide),the DMF will make the fluid pu leather into solid way,it will solidify the pu material.

as the DMF is toxic, then we need clean the DMF by washing it ,then we dry it,until this procedure we got the pu base material.

then we need make a surface pu layer. the method is we coated the pu material on the release paper,this pu layer is half dry,

so it is sticky,we directly use this half dry pu layer coat on the base material,and send it to a bake oven,finally we split the release paper with the first pu layer material,we got the pu leather.

2:second way is dry pu leather manufacturing method

the dry method for producing pu will not require the DMF solvent

1:coat the mixed pu material on the release paper

2: dry the material of last procedure

3:coated the mixed pu material on the release paper again

4:dry the material of last procedure again

5:coated the mixed pu material on the release paper again

6:use above material to coat on the fabric

7:split the pu material with the release paper

then we got the pu leather.

microfiber leather manufacturing process

how to manufacture microfiber leather?

microfiber leather is pu coated microfiber base rather than the pu base ,so similar production flow as pu leather.

Silicone leather manufacturing process

how to manufacture silicone leather?

silicone leather is silicone coated on fabric.

procedure is similar like dry pu leather manufacturing method.

Silicone leather is becoming popular for all upholstery project,such as car seat cover,marine,furniture ,especially for children product.

1:what is synthetic leather

synthetic leather is not genuine leather,it does not include animal leather.nowadays,

synthetic leather is also called faux leather,artificial leather,imitation leather or fake leather.

synthetic leather is totally different from genuine leather. synthetic leather,by material category,can be divided into 4 kinds:

1: pu leather which is made of polyurethane(PU),also is called polyurethane fabric or polyurethane leather.it is pu coated on polyester or other fabric,so it has 2 layers we can say,first layer is pu and second layer is fabric.

2: pvc leather which is made of polyvinyl chloride ,also known as vinyl fabric or vinyl coated fabric

3:microfiber leather is nylon base coated with polyurethane.

4:silicone leather is silicone coated fabric.

so why I prefer synthetic leather.

- I want to protect animals and our environment,you know we have only one world,animals and human beings are closely connected with each other,from the Coronavirus we can learn a lot that we should protect the environment and animals,or we will be hurt by ourselves.so stop killing animal,we can replace real leather with synthetic leather.during the production of real leather,it needs a lot of water,and these water are polluted by chrome tanning agent,it is not good for the environment .and the heat emission rate of real leather factory is very high.

- synthetic leather is non toxic,during the production of our synthetic leather,we need no water,and we do not use heavy metails like chrome,and as our production line is simple and effective,we emit very few heat and carbon dioxide.our product is DMF free,BPA free,phthalates free,these materials are huge damage to our health. our material pass REACH and Rohs or CPSIA test,even the strictest material safety standard we can pass.our material can be used for children’s furniture,playmat etc,so totally non toxic,no bad smell.

- synthetic leather is long life,it is hydrolysis resistant,UV resistant,breathable,for example our silicone leather can be used for outdoor furniture,commercial outdoor seating,as it is water proof,UV resistant,it will not peel off or color fading,physical performance is superb.and our silicone leather is recycable.check below link for confirmation https://www.ecousarecycling.com/procedures-for-silicone-cookware-recycling

- synthetic leather is cost effective.you know real leather is expensive and the usage rate is not good,it will cause many offcut which can not be used for leather products. while synthetic leather usage rate is nearly 100%,there is no holes on the surface,no wastage.

above the reasons that I prefer synthetic leather. below are other useful information of synthetic leather.

how to distinguish pu leather,pvc leather and microfiber leather?

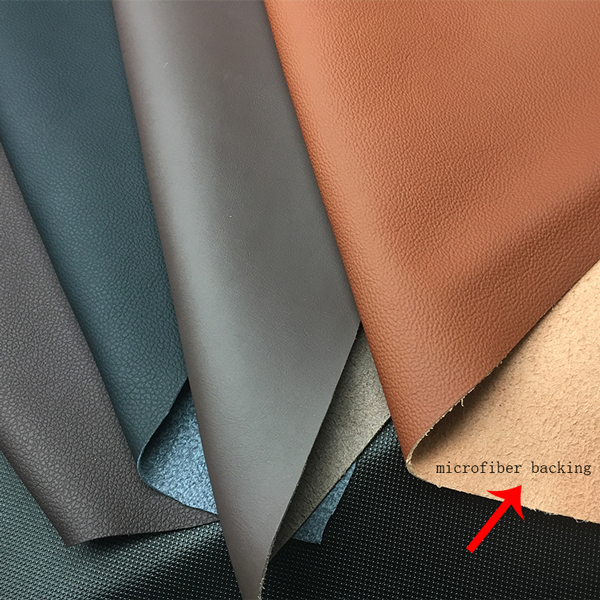

the backing of pu leather ,pvc leather is different from microfiber leather,

because microfiber leather has a microfiber backing,like below picture

however,pu pvc leather has a backing fabric,like polyester or cotton fabric,like below white fabric picture

and how to distinguish pu leather and pvc leather?

the easiest way is burn it, when you burn it, the pu leather will produce white smoke,

however the pvc leather will produce black smoke with a strong smell.